2020 官網(wǎng)升級(jí)中!現(xiàn)在您訪問(wèn)官網(wǎng)的瀏覽器設(shè)備分辨率寬度低于1280px請(qǐng)使用高分辨率寬度訪問(wèn)。

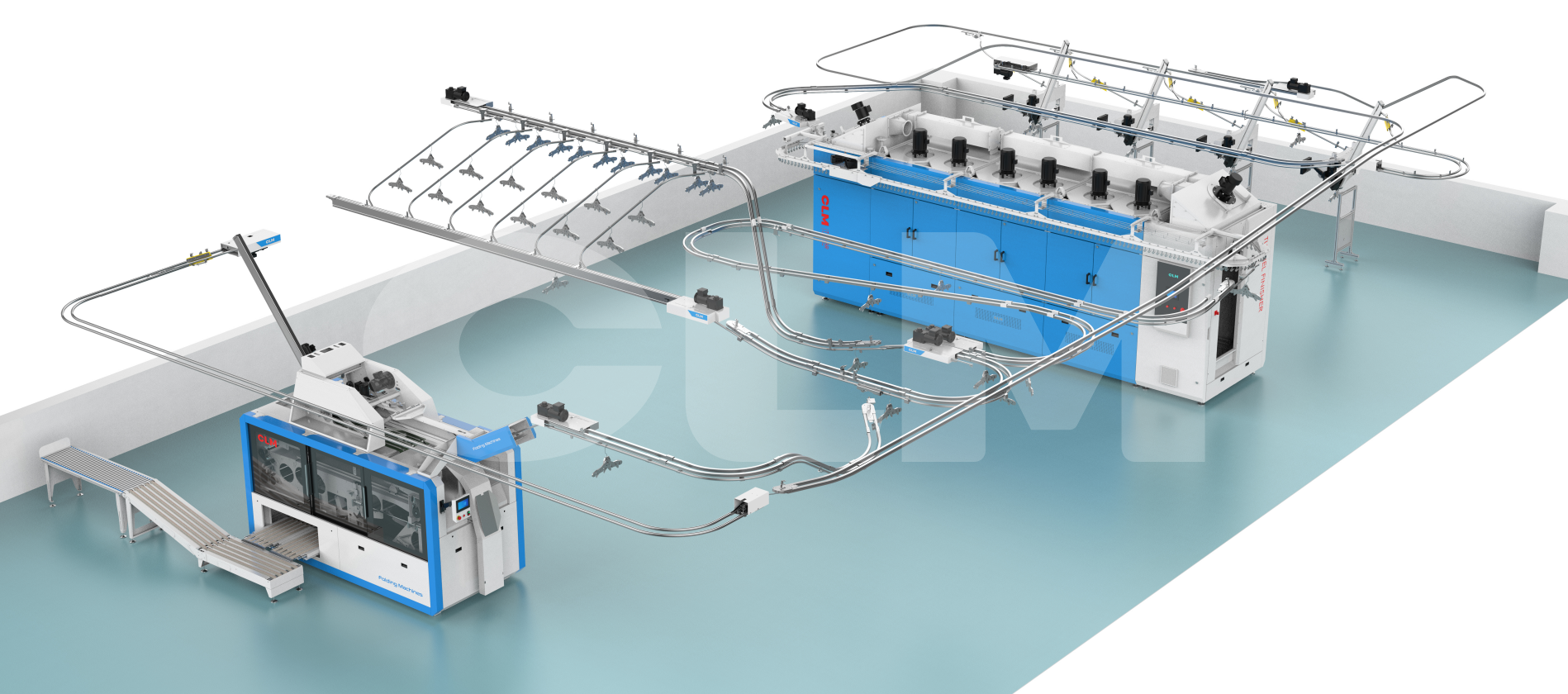

CLM garment finishing linen can automatically dry, iron and fold different kinds and sizes of garments (surgical gowns, white coats, nurse uniforms, hospital gowns, T-shirts, etc ). The newly upgrade automatic identification and sorting functions provide more convenient and efficient solutions for the medical laundry plants.

The popularization of artificial intelligence brings many conveniences to everyone’s life. The new upgrade of the CLM garment finishing line also improves the efficiency of the hospital laundry plants. By the intelligent read-and-write system of the garment loading machine, the garments can be bound to the garment hangers. By reading the RFID chips, the automatic sorting of different kinds of clothes and clothes from different customers can be realized. Also, first-level (distinguishing customers) or second-level sorting (distinguishing departments/sections) can be achieved according to customer requirements. The detailed information will be displayed on the monitor at the feeding station. The feeding stations can be configured according to the working capacity of the laundry plants to face all production peaks.

CLM tunnel finishers use the Mitsubishi PLC control system. When drying, it can automatically identify clothes and pants, and adjust to the corresponding mode. The dual-channel sorting folders can identify the types of clothes and switch to corresponding folding mode and realize classified stacking with no need of human labour, greatly improving the accuracy and efficiency.

The CLM garment finishing line can also be applied to clothes without chips. The employees only need to manually choose the customer information and the following assembly line work can be finished.

CLM will keep innovating and upgrading to build more intelligent laundry plants for all our customers.